Columbia Forest Products is the largest manufacturer of rotary hardwood veneer in North America. Specializing in Northern Appalachian hardwoods, veneers from 1/28″ to 1/42″ in thickness are produced for both domestic and export markets.

Check all available species

ALDER, NATURAL

ANIGRE, FIGURED

ANIGRE, PLAIN SLICE

ASH, SAP, PLAIN SLICE

ASH, SAP, QUARTER CUT

BEECH, AMERICAN

BEECH, EUROPEAN

BIRCH

BUTTERNUT

CEDAR, AROMATIC

CHERRY

CHERRY, ROPEY FIGURED

EUROPEAN WHITE OAK

GUM, RED

HICKORY

JATOBA, FLAT CUT

MAHOGANY, AFRICAN

MAPLE, BIRDS’ EYE

MAPLE, HARD

OAK, RED

OAK, RED, QUARTER CUT

OAK, WHITE

PINE, KNOTTY

POPLAR, YELLOW

SAPELE, PLAIN SLICE

SAPELE, POMMELE

SAPELE, QUARTER CUT, DARK

SAPELE, QUARTER CUT, FIGURED

SAPELE, QUARTER CUT, LIGHT

SYCAMORE, ENGLISH

VERTICAL GRAIN DOUGLAS FIR

WALNUT, AMERICAN BLACK

WHAT MAKES CFP VENEERS SO GREAT?

THE LEADING SUPPLIER OF VENEER IN NORTH AMERICA

ANSI/HPVA defines veneer as “a thin sheet of wood, rotary cut, sliced, or sawed from a log, bolt or flitch.”

Birch, red oak, maple, ash, poplar, cherry and other species of fancy veneer are supplied throughout the decorative plywood, furniture, cabinetry, door and profile-wrap industries.

TYPES OF VENEER

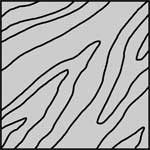

WHOLE PIECE VENEERS

Continuous pieces of veneer peeled from a log using a rotary process.

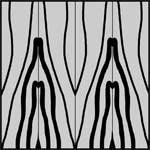

BOOK MATCHED VENEERS

Every other strip of veneer is turned over. This produces a grain pattern that is matched at the veneer joint.

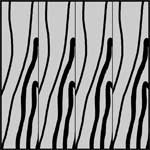

SLIP MATCHED VENEERS

Each strip is laid out side by side (without turning over). This produces a repetitive pattern.

SPLICED VENEERS

Composed of several pieces of veneer varying in width that are glued together to form a whole sheet. The way they are laid out determines the final look of the veneer.

SALES TEAM: VENEER DIVISION

WHERE TO BUY

Whether you're a large contractor or a DIY hobbyist, Columbia Forest Products are conveniently available throughout North America. Find your wholesale distributor or Home Depot store here!