Columbia Forest Products is the largest manufacturer of rotary hardwood veneer in North America. Specializing in Northern Appalachian hardwoods, veneers from 1/28″ to 1/42″ in thickness are produced for both domestic and export markets.

The leading supplier of hardwood veneer in North America

ANSI/HPVA defines veneer as “a thin sheet of wood, rotary cut, sliced, or sawed from a log, bolt or flitch.”

Birch, red oak, maple, ash, poplar, cherry and other species of fancy veneer are supplied throughout the decorative plywood, furniture, cabinetry, door and profile-wrap industries.

Types of Veneer

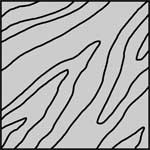

Whole Piece Veneers

Continuous pieces of veneer peeled from a log using a rotary process.

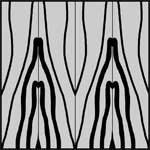

Book Matched Veneers.

Book Matched Veneers.

Every other strip of veneer is turned over. This produces a grain pattern that is matched at the veneer joint.

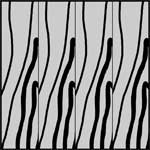

Slip Matched Veneers.

Slip Matched Veneers.

Each strip is laid out side by side (without turning over). This produces a repetitive pattern.

Spliced Veneers.

Spliced Veneers.

Composed of several pieces of veneer varying in width that are glued together to form a whole sheet. The way they are laid out determines the final look of the veneer.

Top Species

- Maple

- Birch

- Red Oak

- Cherry

- Alder

Veneer Species Guide – Columbia Forest Products

Veneer Grades

- Select Veneer is composed entirely of heartwood or sapwood and is matched for both grain, pattern and color.

- Uniform Veneer is also composed of entirely heartwood or sapwood, but is matched for color only.

- Natural Veneer is composed of both heartwood and sapwood and is generally less expensive than select or uniform veneers.

- Paint Grade Veneer has a smooth enough finish so none of the wood grain characteristics show through the paint.

- Stain Grade Veneer is meant to take a clear or tinted stain and still show the natural characteristics of the wood.

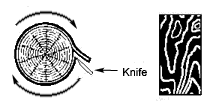

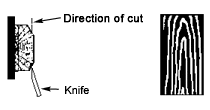

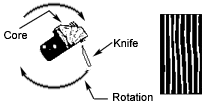

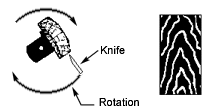

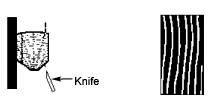

How Veneer is Cut

Rotary Cut VeneersEntire log is peeled producing a continuous ribbon of veneer. |

|

Plain Sliced VeneersLog is cut in half lengthwise. Each half is then sliced lengthwise producing a veneer with a unique grain pattern. |

|

Rift Sliced VeneersLog is cut into quarters lengthwise then sliced at a 90-degree angle to the grain. This produces a fine pencil stripe effect. Both plain and rift sliced veneers are reserved for high-grade “fancy” panels. |

|

Half Round Sliced VeneersThis is a variation of rotary cutting. This effect results from the log being mounted off center in the lathe so only one side of the log is sliced at a time. |

|

Quarter Sliced VeneersThe quarter log is mounted so the growth rings strike the cutting knife at right angles. This produces a series of stripes in the veneer. |

|